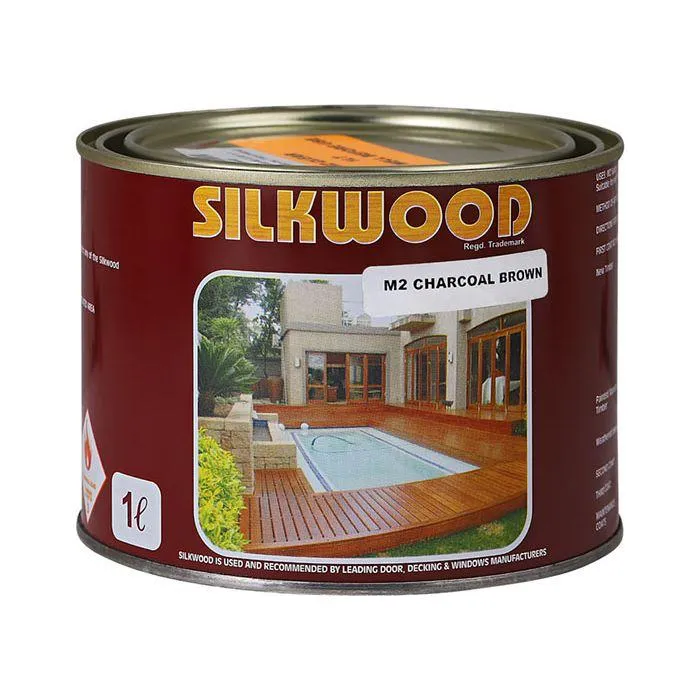

A universal maintenance / DIY water-repellant wood sealer/wood treatment that dries to a semi-matt finish.

Application Method :

- Brush

- Roller

- Spray

Silkwood sealers range from those for industrial application to those for DIY or Domestic use.

The continuous upgrading of the wood treatment product range,

and the inclusion of customised raw material components

has created a range of products that are outstanding in terms of:

Minimising wood degradation such as cracking, end splitting, warping and grain rise

Durability

Cost Performance

Low Maintenance

APPLICATION:

Silkwood Woodsealers / Wood Treatments should be applied in accordance as per the product requirement.

The surface of the wood must be dry, clean and free of old products, etc.

Prior to applying the first coat of Silkwood, always ensure that the product has been sufficiently stirred as some in-can settling of the pigmentation can occur.

The first coat should be allowed to dry for at least 24 hours before re-applying.

When applying the Silkwood , it should be applied thinly and worked into the wood, applying too thickly will result in a an extremely extended drying period.

It is recommended that a third coat be applied for maximum protection.

South African climatic extremes will require periodic maintenance to maximize protection.

Maintenance should be done when wood surface appears faded and dry.

It should not be necessary to sand the surface when applying maintenance coats the surface is only moderately dirty use a green pot scouring pad to lightly rub the surface down.

If another type of wood sealer has been previously applied to the wooden surface, it is recommended that the old product must be sanded down before applying Silkwood.

The coverage is approximately 6-8M² per litre, per coat, depending on the material.

Brushes and rollers should be cleaned with either turpentine or white spirits after using wood coating. Dilution of the products is not recommended.